FilterPress

The BIBKO® chamber filter press for cleaning residual/wash water with the separation of the finest particles brings the recycling of residual concrete to the highest level.

After separating aggregate particles up to 0.2 mm in size, the sludge water can be cleaned using a chamber filter press. The fine particles contained in the sludge water are captured, so that purified water is available after filtration. Sludge water is supplied to the facility either directly or from a mixing tank. By further treating it is then possible to reduce high pH value of the purified water.

The chamber filter press removes cement and sand fine particles from the sludge water. It consists of several plates with filter fabric arranged in a row. During the process, these are compressed and the water is forced out. The contained fine particles are separated in the form of solid filter cakes. Once the chambers are completely filled, the cakes are released and the water drains into the tank.

Optionally, the FilterPress can be supplied in an insulated container including a staircase. The container can be equipped with a self-closing door system for the ejection of filter cakes as protection against freezing. Other options for optional equipment are a densitometer, a filter fabric acidification system, a pH neutralization system or water tanks.

FILTRATION OF PARTICLES FROM A FEW µM SIZE

ACQUISITION OF REUSABLE RAW MATERIALS

HIGH FILTRATION CAPACITY

LOW OPERATING AND MAINTENANCE COSTS

OPTIONAL NEUTRALIZATION SYSTEM

CONTAINER VERSION ON REQUEST

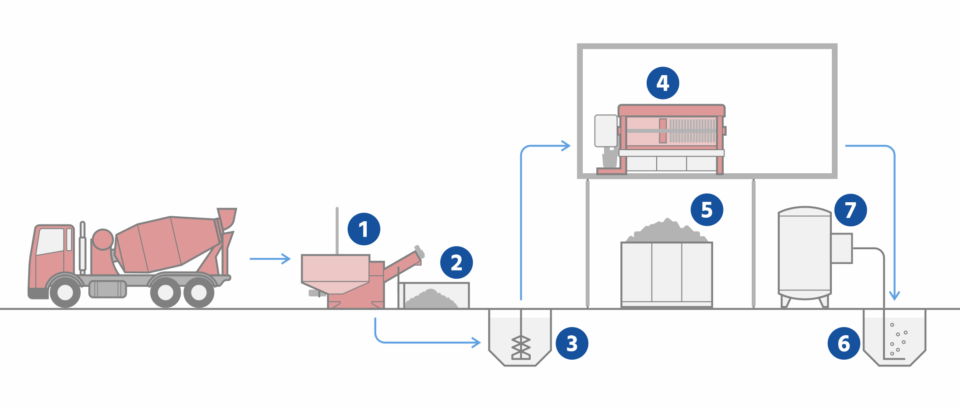

RECYCLING PROCESS

- residual concrete recycling equipment BIBKO® Comtec or BIBKO® RWS

- separated particles of aggregate, gravel and sand

- mixing tank for sludge water discharged after washing

- chamber filter press BIBKO® FilterPress

- reservoir for fine sludge particles captured by filtration after compression into the form of filter cakes

- tank for water cleaned by the filtration process

- optional neutralization system to reduce the pH of the obtained purified water